The role of free cooling in data centres and why it is an excellent option

With the ever-growing appetite for data, data management needs to be handled with care. One also needs to focus on the amount of carbon footprints data centres are leaving behind. To ensure that data management systems are managed efficiently, we must understand how free cooling in data centre works. Like everything, we, as human beings, wish to avail things for free. So, why pay for a normal compressor-based cooling, when you can protect your servers from heating for free? In this extensive article, we are going to discuss the challenges of running a data centre and how, with the help of free cooling, we can work towards a sustainable future.

The challenge

Since the onset of the pandemic, there has been a rapid increase in carbon footprints. This poses a challenge to the sustainable development of human civilization. As we are already aware, the cooling energy consumption takes up around 30–50% of the total consumption of data centres because of the inefficient cooling system. It is here that we turn to free cooling, which is an efficient solution for reducing the power consumption of cooling systems & maintaining the optimized Power Usage Effectiveness (PUE).

Free cooling

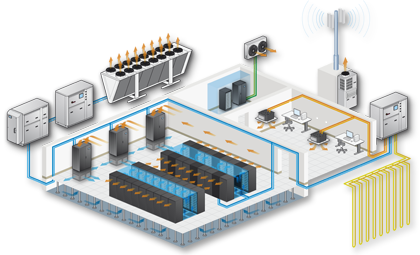

Free cooling is a method in which outside resources are used in a data centre for cooling purposes. AdaniConneX is aware that the data centre industry is one of the most power-consuming IT industries that requires a lot of power to run critical IT load. While processing this data, it generates a lot of heat that needs to be dissipated.

There is, of course, a cost associated with the initial investment. Free cooling requires the procurement of both a chiller and an air-fluid cooler which increases the project's cost. If you can summon the foresight to consult an expert in the area to perform the energy-saving calculations, you may discover that these units have a payback period of one to two years. AdaniConneX is providing customer-centric solutions like meeting global standards, best-in-class power usage effectiveness, usage of green energy, and building cost-effective solutions.

A lot of heat is a lot of loss

Data centres emit a lot of heat on a daily basis. The servers are often under tremendous strain, and as a result, they produce a significant amount of heat that must be managed. Until recently, compressor-based cooling solutions were the only way to cool servers. They need a great deal of energy and, as a result, become quite costly very quickly.

In some data centres, the operational budget quickly mounts the expenses of encoding. Achieving 100% free cooling for data centre is not possible but various economizers can be used to reduce power consumption. It can be carried out through an airside economizer or a waterside economizer. When the ambient temperature is more favourable for heat rejection in white space by using an airside economizer, fresh air can be treated and supplied to the load.

When outside water resources are used, a waterside economizer can be used in a chiller system which can efficiently reduce the chiller load, resulting in less power consumption.

Benefits of free cooling

The benefits of free cooling are obvious. There is no need to cool the hot air because the outside air is used. You simply let it go. This saves a significant amount of both energy and money. As a result, data centre companies can charge less for their services.

Free cooling is also a greener, more environmentally viable option due to its lower energy consumption. Opting for free air cooling would save money since 40% of data centre power usage was used on cooling systems.

Proposed adiabatic cooling solutions:

The system improves the performance of all air-cooled equipment operating in adverse conditions. Considering water storage at the Chennai site, the provision shall be maintained for the Adiabatic solution to be implemented, if required during peak summer conditions.

Benefits of adiabatic cooling:

- Reduction of system power input: a 10°C temperature drop delivers a 13% reduction in power consumption, bringing immediate cost savings.

- Delivery of design capacity without interruptions when the ambient air temperature reaches summer peaks above design.

- Enhanced compressor life due to reduced discharge temperature.

An adiabatic cooling system is proposed to enhance the free cooling of an air-cooled chiller’s efficiency, which is obtained by humidifying ambient air going into heat rejection coils.

The ambient air is humidified and cooled down, without incurring any additional energy cost by passing through wet pads. Thus, the air is delivered at a lower temperature to the free cooling and the condensing coils, achieving respectively a higher free cooling capacity and a more efficient compressor operation. With a chiller operating at full load or at peak load during summers, one can expect annual energy savings of 60-65%, in comparison to a standard air-cooled chiller.

Cooling technology used in Chennai data centre:

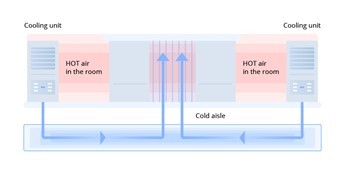

AdaniConneX’s Chennai data centre has achieved efficient cooling by physically isolating the possibility of the hot or cold air mixing and driving it directly to and from the PAHU unit.

All data halls are provided with PAHU units with an Underfloor cooling system. The units are provided with supply air temperature logic to maintain the cold aisle temperature as per ASHRAE standards. It substantially reduces the issues with hot spots and air mixing.

All critical areas in the data centre building are provided with cooling via chilled water-based or air-cooled chillers that are located at the terrace level of the building. The use of air-cooled chillers in place of the water-cooled chiller in the Chennai data centre is to minimize the consumption of water as the Chennai region is already facing water scarcity for the past couple of years.

The Government of India as well as the World Resource Institute have highlighted that Chennai suffers from water scarcity. Keeping this in mind, AdaniConneX uses an air-cooled chiller instead of a water-cooled chiller. This is done so that we don't compromise on the performance of the data centre. Climate change scenarios have been considered while designing the project.

In a nutshell, free cooling is simple to set up and delivers automatic free cooling when the outside temperature falls below a certain threshold. A free cooler can be delivered brand new or retrofitted to an existing chiller system.

Related Blogs